Industrie 4.0

The focus of the Think Tank in 2014 and 2015:

Industrie 4.0 | Controlling in the age of intelligent networking

The Dream Car report of the Think Tank on the topic "Industrie 4.0" is available for free download:

Dream Car report of the Think Tank of the ICV in 2015:

Industrie 4.0 | Controlling im Zeitalter der intelligenten Vernetzung

Industrie 4.0 | Controlling in the Age of Intelligent Networks

On the way to the fourth industrial revolution

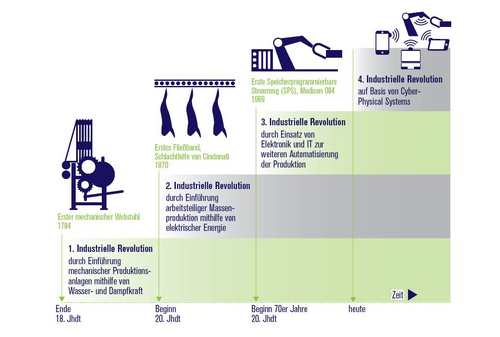

Industrie 4.0 is the mega trend in production and stands for intelligent networked factories and value chains. Experts predict a productivity increase of up to 50%. Figure 1 illustrates the path to the fourth industrial revolution.

The starting point of every industrial revolution was the use of new technologies and the associated with it improved organization and management of entire value chains:

- The first industrial revolution

At the end of the 18th century, the first industrial revolution was launched with the introduction of mechanical production facilities. The development of the steam engine was decisive. With the aid of the steam engine, the heat energy contained in the steam could be converted into mechanical work. This resulted in the possibility of mechanization of manual work by machines.

- The Second Industrial Revolution

At the beginning of the 20th century the introduction of mass production by means of electrical energy was a major driver of the second industrial revolution. A revolution characterized by a work organization is often mentioned in this context. The Henry Ford production line and the principles of the industrial work organization by Frederick W. Taylor (Taylorism) were characteristic here.

- The Third Industrial Revolution

At the beginning of the 70s of the 20th century, the third industrial revolution started and has continued until today. This was due to the increasing use of electronics and information and communication technology, which enabled an increasing automation of production processes. This led, on the one hand, to further rationalization and, on the other hand, to serial production with a variety of variants.

- The fourth industrial revolution

After mechanization, electrification and computerization - within the framework of Industrie 4.0 - the focus is now on the networking of production processes. Through intelligent networking, value-added processes are to be planned and controlled in real-time. This allows more flexible and efficient production processes. This is realized by so-called Cyber-Physical Systems (CPS). CPS refers to the integration of embedded information technologies into objects, materials, devices and logistics, coordination and management processes as well as their networking.

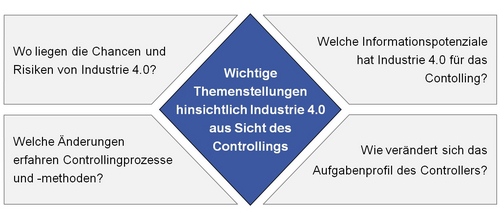

Topics regarding Industrie 4.0 from the point of view of controlling

Despite the integration of principles of artificial intelligence, man and his role as a qualified decision-maker remains a key factor in the production environment. However, it is predicted that its role and work will be fundamentally changing within Industrie 4.0 (see Spath et al., 2013). With our work in the Think Tank, we would like to find out how this development affects the controlling and the controller. In order to elaborate on this, we will deal with the topics listed in Figure 2.